- Details

- Application

- Specification

-

AL6061All aluminum chassis

-

7INCHTouch screen

-

GO/NGAutomatic determination

-

1PaHigh resolution

-

USBData storage

-

RS485Serial communication

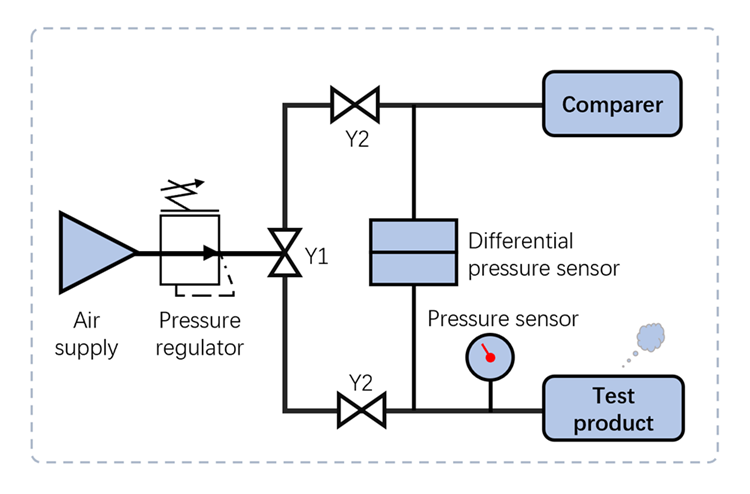

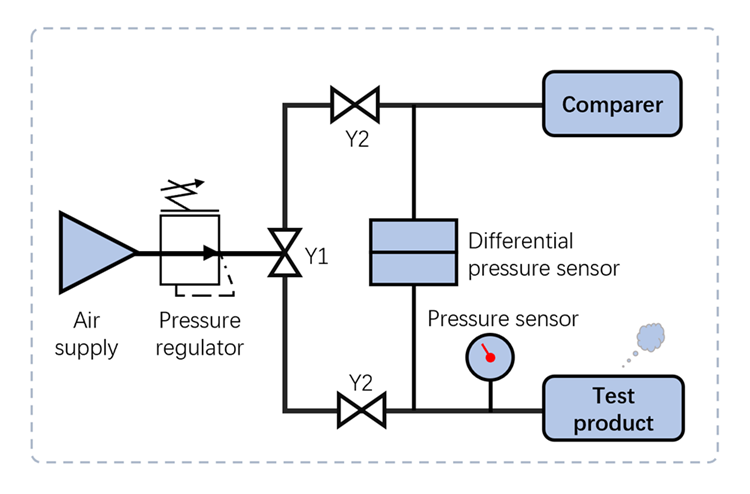

Test schematic

Open Y1 and Y2, and simultaneously charge a certain pressure of gas into the standard workpiece and the tested workpiece with equal volumes. Then close Y2. After the pressure is balanced and stabilized, measure the pressure difference between the standard workpiece and the tested workpiece. This difference is the actual leakage value. Since the sensor for obtaining the pressure difference is independent, this test method is not affected or limited by the inflation pressure and has a very high accuracy.

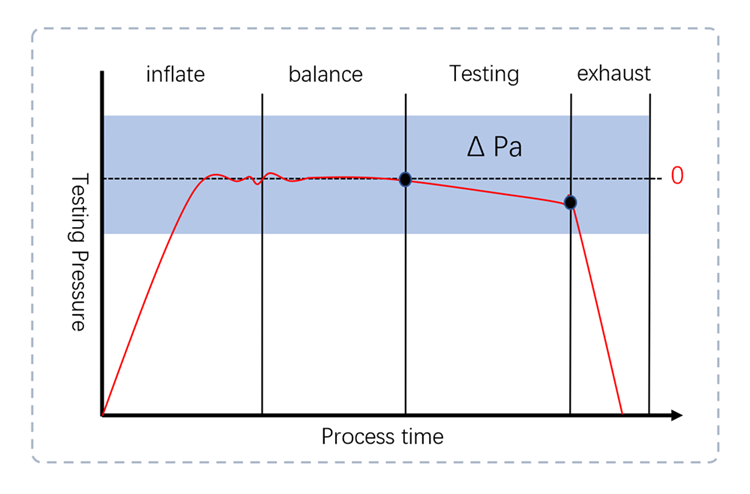

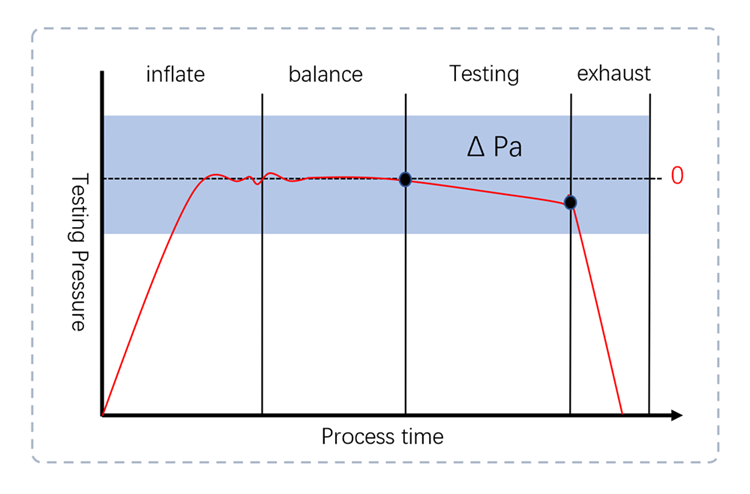

1、Delay Time: The time to wait for the fixture to clamp the product, with a setting range of 0.1 - 999.9 seconds.

1、Delay Time: The time to wait for the fixture to clamp the product, with a setting range of 0.1 - 999.9 seconds.

2、Inflation Time: Pressurize the product according to the preset pressure, with a setting range of 0.1 - 999.9 seconds.

3、Equilibration Time: The time to wait for the airflow and air pressure to stabilize, with a setting range of 0.1 - 999.9 seconds.

4、Measurement Time: Detect the leakage amount △P or leakage rate sccm within a certain period, with a setting range of 0.1 - 999.9 seconds.

5、Exhaust Time: The time for exhausting gas after the test, with a setting range of 0.1 - 999.9 seconds.

ATC800 series air leak tester is widely used in parts leak detection of auto parts, mobile phones, smart wearables, smart watch, earphones/headphones, medical equipment, electronic appliances, household appliances, automotive three-electric system,gas appliances and other industries.

Technical Parameters

|

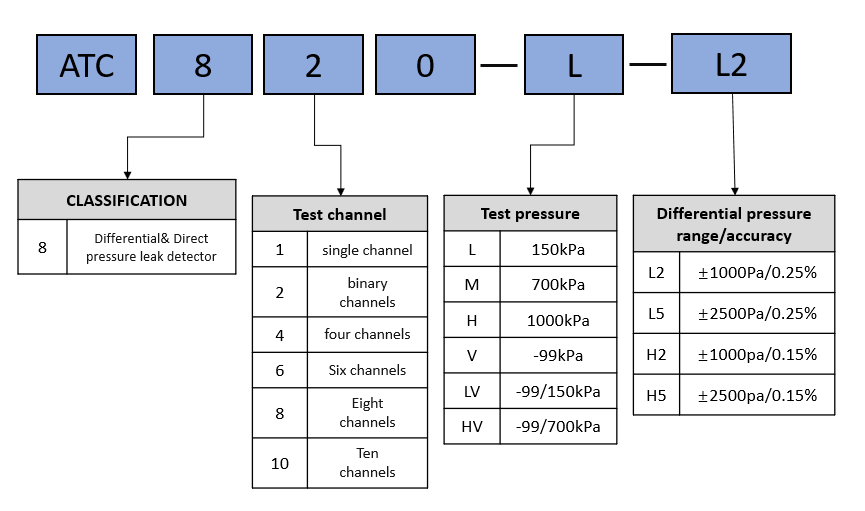

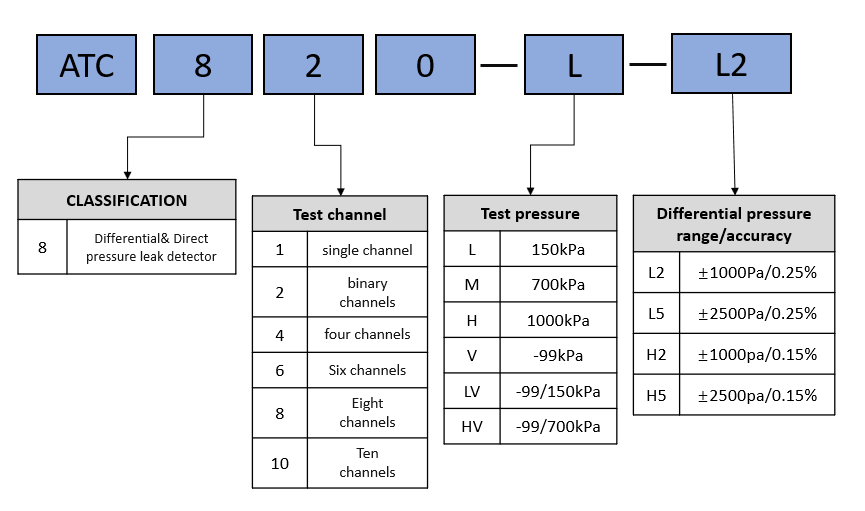

Model Specification

|

ATC820-L-L2

|

|

Machine Type Classification

|

Dual channel leak tester

|

|

Measurement Method

|

High - Precision Differential Pressure Measurement Method

|

|

Pressure Regulation Method

|

Selectable between High - Precision Mechanical Pressure Regulation and Electronic Pressure Regulation

|

|

Pressure Sensor

(Pressure Display)

|

Test Pressure: 2 - 150 KPa

Pressure Units: kPa, mmH2O, Torr, PSI

Pressure Resolution: 0.1 KPa

Display Accuracy: 0.5% F.S

|

|

Differential Pressure Sensor

(Leakage Measurement)

|

Units: Pa, Pa/s, sccm (mL/min)

Differential Pressure Range: ±1000 Pa

Differential Pressure Resolution: 0.1 Pa

Test Accuracy: 0.25%F.S o

Repeat Accuracy: ≤±2 Pa within 50 Pa

|

|

Leakage Rate Measurement

|

Equivalent Volume Range: 0.1 - 999.9 mL

Leakage Rate Test Range: 0.001 - 999 sccm

Leakage Rate Resolution: 0.001 sccm

|

|

Time Setting

|

Delay Time: 0.1 - 999.9 sec

Inflation Time: 0.1 - 999.9 sec

Equilibration Time: 0.1 - 999.9 sec

Detection Time: 0.1 - 999.9 sec

Exhaust Time: 0.1 - 999.9 sec

|

|

Screen Size

|

7 - inch Color Touch Screen

|

|

External Control I/O

|

5 - way Input and 6 - way Output

|

|

External Control Connector

|

DP37 Connector, USB, RS485, RJ45

|

|

Data Transfer

|

U Disk Data Transfer Function

|

|

Communication Function

|

RS485 Communication

|

|

Alarm Function

|

Pass/Fail Alarm Output

|

|

Auxiliary Function

|

Bubble Leak Detection Function

|

|

Power Input

|

AC220V/50Hz

|

|

Power

|

Approximately 40W

|

|

Air Source Used

|

≥0.4MPa Stable and Dry Compressed Air

|

|

Test Port

|

Φ4, Φ6, Test Gas Tubes Are Selectable (Default Φ4 Pressure - Resistant and Constant - Temperature Gas Tube)

|

|

Operating Environment

|

5~30°C/20~80%RH (Non - Condensing)

|

|

Product Size

|

300×225×450mm(W*H*D)

|

1、Delay Time: The time to wait for the fixture to clamp the product, with a setting range of 0.1 - 999.9 seconds.

1、Delay Time: The time to wait for the fixture to clamp the product, with a setting range of 0.1 - 999.9 seconds.